ST2742B Automatic Powder Resistivity Tester

AddDate: 2022/12/1 14:56:30

Hits: 11267

I. Product Introduction

Product Information

Name: ST2742B four probe method [four terminal method] electric powder resistivity tester

Brand: Suzhou Jingge

Product features

ST2742B electric powder resistivity tester is a measuring and analyzing instrument that uses four terminal method or four probe method to test the powder "resistivity pressure" performance curve.

The four terminal method complies with GB/T 24521-2009 and YS/T 587.6-2006 relevant national and industrial standards. The internationally used current and voltage four terminal measurement method (the current source and voltmeter of the instrument are connected to the electrode from an independent loop and contact the sample at the same time) can eliminate the error caused by the conduction resistance of the electrode and the connecting wire, overcome the shortcomings of the traditional two terminal method for measuring powder resistivity instrument, and can truly and accurately measure the resistivity of the powder sample, so the repeatability is also good.

The design of the four probe method test bench complies with the principle and specification of powder resistivity test in the latest GBT 30835-2014 "Carbon Composite Lithium Iron Phosphate Cathode Materials for Lithium Ion Batteries”, with reference to GB/T 1551-2009 "Method for Measuring the Resistivity of Silicon Single Crystals", GB/T 1552-1995 "DC Four probe Method for Measuring the Resistivity of Silicon and Germanium Single Crystals", and with reference to A S. T. M standards.

Four probe method synchronous pressure continuous test powder "resistivity pressure curve,"

Industry standard test method for powder resistivity.

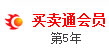

Product Photograph

Real picture of ST2742B electric powder resistivity tester

Product close-up

Function display Operation - Adjust the cup capacity to control the feeding amount

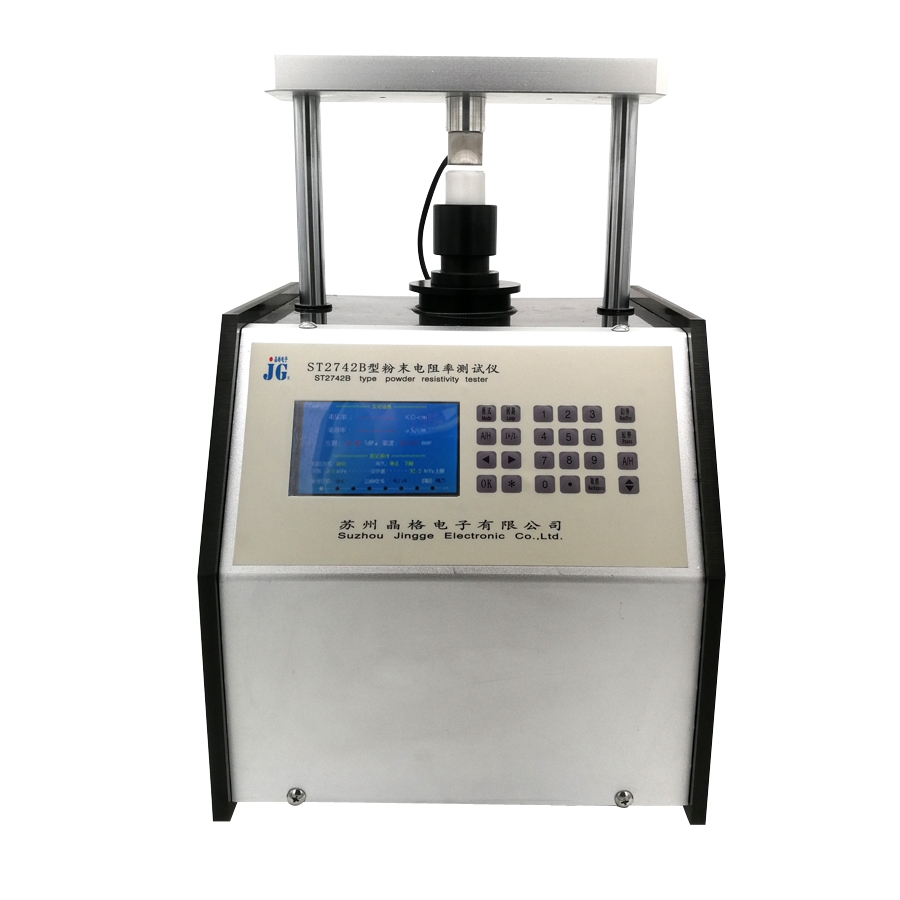

ST2742B software interface

ST2742B setting interface

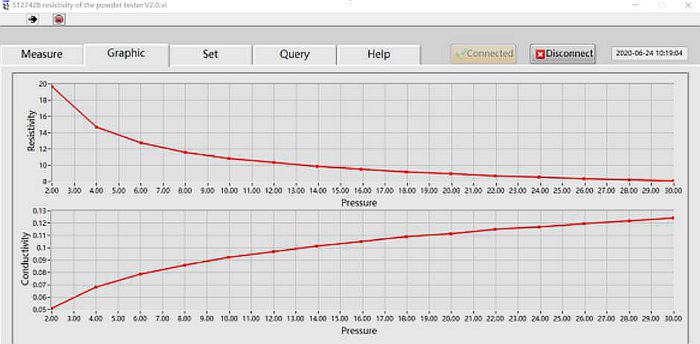

ST2742B software pressure conductivity curve

II Overview

2.1 Basic functions and standards:

ST2742B electric powder resistivity tester is a measuring analyzer that uses four terminal method or four probe method to test the powder "resistivity pressure" performance curve

Instrument composition: the whole instrument consists of four probe (four terminal) host and electric powder test bench.

Host: it is the core part of the electrical control display of the whole system, mainly composed of precision constant current source, high-resolution ADC, embedded single-chip system unit, pressure detection, thickness detection, color LCD display window and other units.

Powder test bench: It is a device connected to the test host, used to clamp semiconductor powder (including polymer powder and metal powder), apply electric automatic pressure (tablet pressing), and conduct resistivity test synchronously (hereinafter referred to as the test bench).

The test bench is composed of powder standard container, electrode, pressurizing mechanism, pressure detection, thickness detection, connecting cable and other units.

2.2 Advantages:

1) The design of the test bench complies with the national standards and industrial specifications. There are two items as follows:

The four terminal method complies with GB/T 24521-2009 and YS/T 587.6-2006 relevant national and industrial standards. The internationally used current and voltage four terminal measurement method (the current source and voltmeter of the instrument are connected to the electrode from an independent loop and contact the sample at the same time) can eliminate the error caused by the conduction resistance of the electrode and the connecting wire, overcome the shortcomings of the traditional two terminal method for measuring powder resistivity instrument, and can truly and accurately measure the resistivity of the powder sample, so the repeatability is also good.

The four probe method test bench complies with the principle and specification of powder resistivity test in the latest GBT 30835 - 2014 "Carbon Composite Lithium Iron Phosphate Cathode Materials for Lithium Ion Batteries", with reference to GB/T 1551 - 2009 "Method for Measuring the Resistivity of Silicon Single Crystals", GB/T 1552-1995 "DC Four probe Method for Measuring the Resistivity of Silicon and Germanium Single Crystals", and with reference to A S. T. M standards.

Four probe method synchronous pressure continuous test powder "resistivity pressure curve,"

Industry standard test method for powder resistivity.

2) All parameter settings and function conversion of the instrument are input by digital keyboard; It has zero position and full degree self calibration functions; Full automatic range switching of voltage and current; The test results are displayed directly on the color LCD screen.

3) The pressure mechanism is electrically operated, and the pressure (pressure) is stable, adjustable and maintainable. The electronic sensor automatically and synchronously detects and displays the pressure (pressure) value and sample height value. Therefore, this test bench can simultaneously test the resistivity while pressurizing, which can facilitate the mapping of the "resistivity pressure" performance curve of powder samples; It can also be used as a tool for powder pressing.

4) This tester is equipped with a complete set of PC software, so it can not only be operated independently (offline), but also be connected to PC software, automatically saving current test data, querying and statistical analysis of historical data, printing test reports, etc!

2.3 Scope of application:

This instrument has the characteristics of high measurement accuracy, simple operation, good stability, good repeatability, and convenient use of one machine for multiple purposes. It is also a new feature different from the previous similar test bench! This instrument is applicable to carbon plants, coking plants, petrochemical plants, powder metallurgy plants, colleges and universities, and scientific research departments. It is an important excellent tool for testing and analyzing the quality of solid and powder samples.

III. Technical Parameters

3.1. Measuring range and resolution of resistivity

Resistivity: 15.0*10- 6~200 . 0*103Ω-cm resolution 1.5*10-6~0. 1*103Ω-cm

(1 .0*10-6 ~200. 0*101Ω-cm resolution 0.1*10-6~0 .1*101Ω-cm)

3.2. Measurement range division and error level of resistivity

| Full scale display | 200.0 | 20.00 | 2.000 | 200.0 | 20.00 | 2.000 | 200.0 | 20.00 |

| Maximum extended range | KΩ-cm | Ω-cm | mΩ-cm | |||||

| Fundamental error | ± 2% reading ± 4 words | ± 1.5% reading ± 4 words | ± 0.5% reading ± 4 words | ± 0.5% reading ± 4 words | ||||

3.3. Digital voltmeter:

⑴ Range: 10mV ~ 100mV, automatic

⑵ Display: 4 significant digits, the maximum display is 999.9, and the decimal point and unit are displayed automatically

3.4. CNC constant current source

Current output: DC current 0.1mA~1000mA is adjustable, and the system automatically adjusts step by step.

3.5. Some parameters of powder test bench:

(1) Sample composition: There is no limit to the composition, but it shall not contain any component that may corrode the test bench and electrode.

(2) Particle size of sample: It is recommended that the particle size is less than 40 meshes to more than 60 meshes (standard screen), and other particle sizes are also acceptable!

(3) Sample container: inner diameter: φ11. 28mm (S=1. 0cm2) Height: 0~20mm adjustable, with height sensor monitoring, measurement error: ± 0.02mm.

(4) Test pressure range: 30Mpa, P=0~30Mpa, adjustable.

(5) The pressure mechanism is electrically operated and the pressure is stable and adjustable. The pressure can be set in steps and at multiple points automatically at one time.

The four digit effective display number is 00.00~30.00MPa, with a respective rate of ± 0.01 MPa.

3.6. Tester shape and weight

Front width*long*Total height=300mm*310 mm*470mm Weight=15Kg

3.7. Power supply:

Power consumption:<50W Input: 220V ± 10% 50Hz (110V ± 10% 60Hz)

3.8. The working conditions of the instrument are:

Temperature: 0-40 ℃ Relative humidity: ≥ 60%

There should be no strong electromagnetic interference in the studio, and the power supply should not be shared with high-frequency equipment.

IV. Contact information and purchase channels:

Sales Manager: Grace Zheng

Tel.:+8618762109211

Email: zhengjingjing@szjgdz888.com

Alibaba Store: https://szjgdz.en.alibaba.com

| Product Order: | ||